Description

Wagner- Reinhardt-Technik:

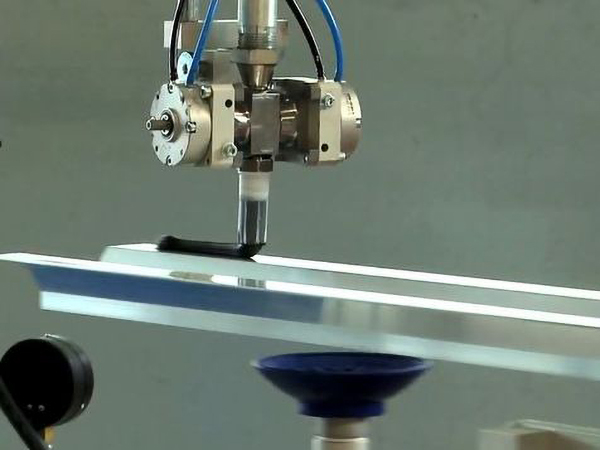

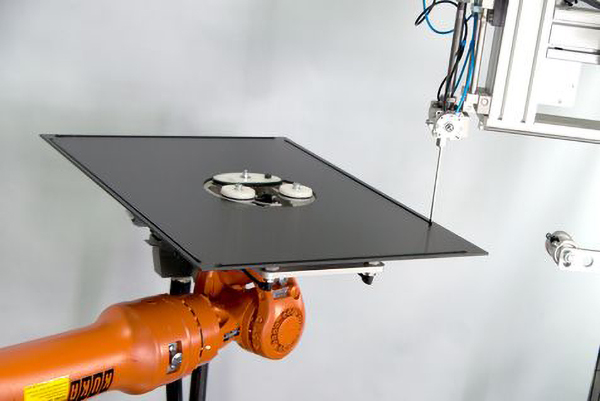

LSR system for proportioning and mixing in a 1: 1 ratio of bicomponent silicones: the best solution for injection molding.

This process offers the highest levels of automation and the greatest freedom of product design.

The fields of application are many and range from baby pacifiers, TV remote controls, diving glasses, through technical products such as gaskets, insulators, membranes, technical fabrics and various medical devices, up to translucent products in the lighting sector.

The range of LSR units ensures a utilization of the material present in the drum greater than 99.5%, providing the highest mixing quality and a high reproducibility of the process.

Advantages

• Compactness and sturdiness

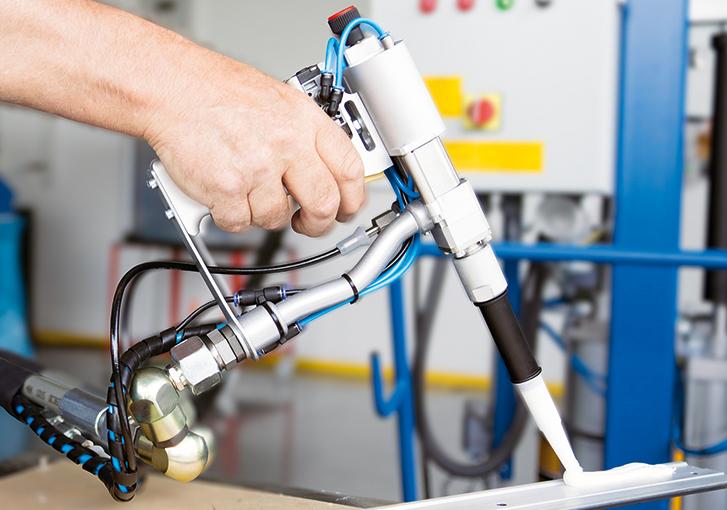

• Quality, precision and constancy of mixing

• Simple and intuitive management of the main process parameters

• Significant product savings

LSR is equipped with piston pumps powered by electric motors with stroke control. The electronically controlled drive ensures simultaneous emptying of the drums of the two products.

The picking and dosing of the material take place directly from the drums: the

result is a compact design and reduced dimensions.

The feeding and mixing of the two components at room temperature is one of the characteristics with which LSR responds to the growing needs of the market.

The LSR range always ensures the highest level of mixing in terms of quality for injection molded materials.

In combination with the pneumatic drum support (optional) which saves an additional 50% of the residual product deposited in the drum itself, LSR reaches 99.5% of the total product used.

LSR lends itself to multiple fields of application while maintaining process reliability and reproducibility.

Reviews

There are no reviews yet.