Description

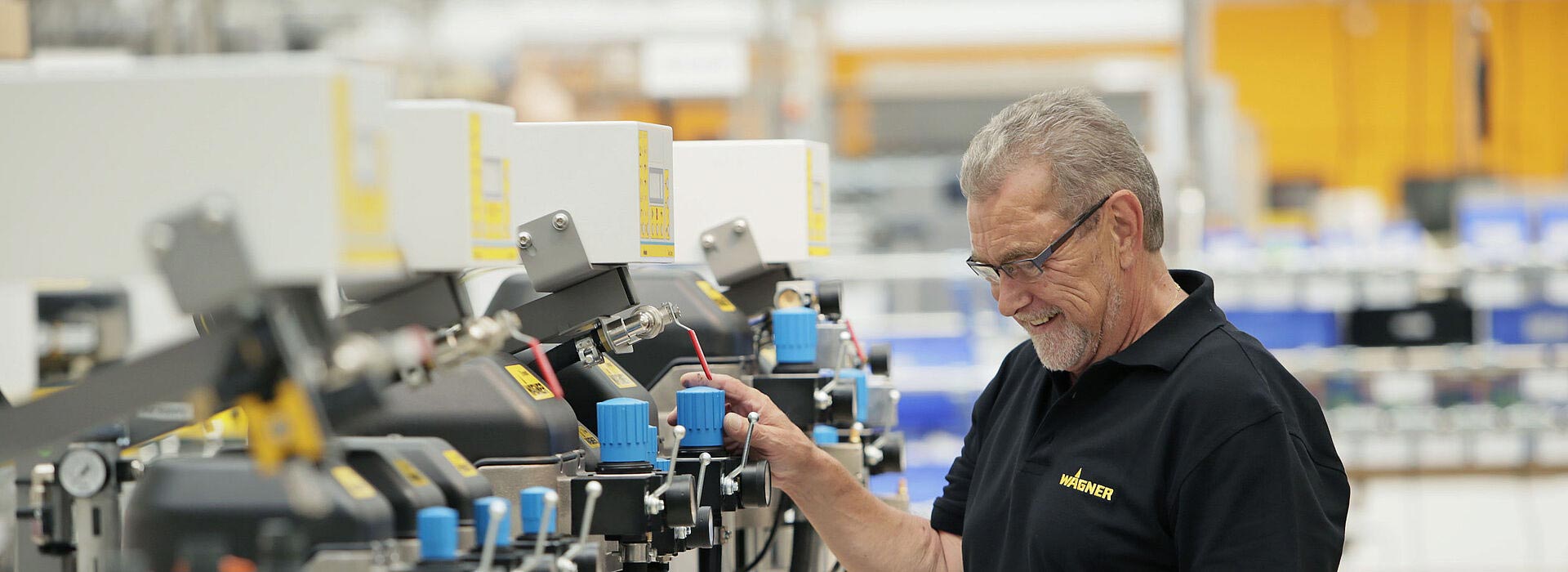

Wagner everything for extrusion

We are able to offer the ideal solution for the extrusion of any fluid:

• Inks

• Putties

• Reactive paints

• Primers

• Adhesives

• Chemicals

• Products with high or low viscosity

• Products with low or high solids content

• Silicones

Pumps, extruders, pressing plates, mechanical and electronic mixing systems (2K, 3K and 4K), guns, product heating systems, pipes and a wide range of accessories… but not only!

The long experience acquired in 30 years of success allows it to design and build complex and complete systems for extrusion, transfer, spraying of fluid products (pasty and not).

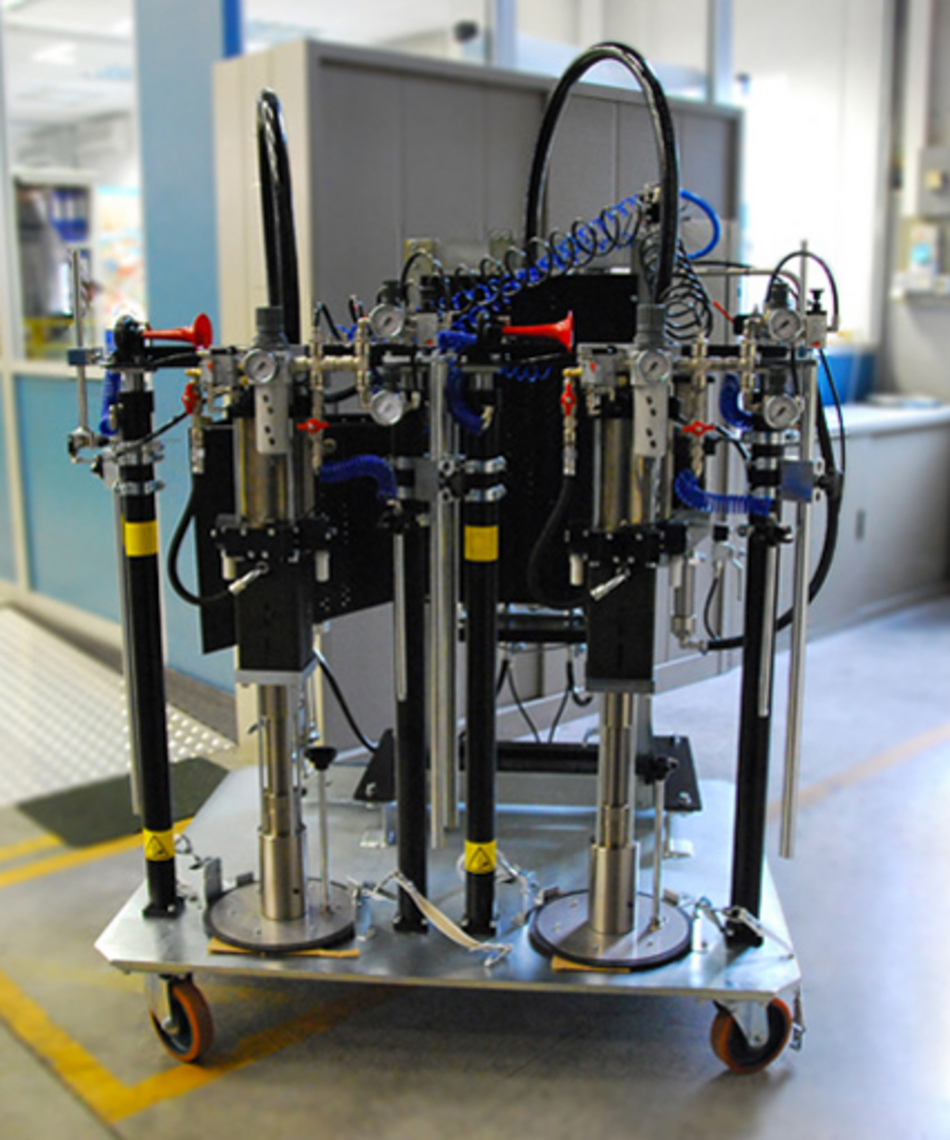

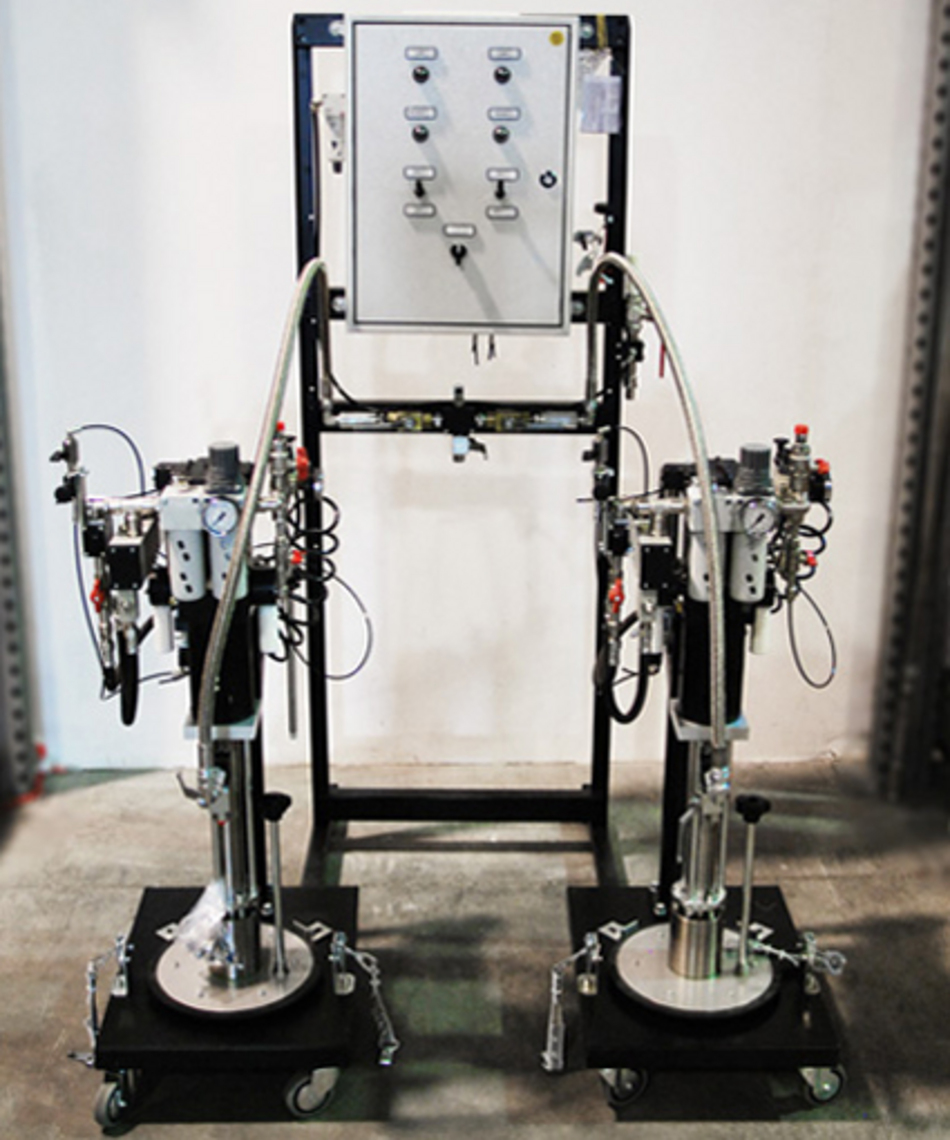

Systems designed for the extrusion of single and two-component adhesives whose pasty pasty components are contained in 25-liter drums.

Two pressure plate pumps suck the components directly from the 25 liter drums and feed the proportioning gear pumps.

The gear pumps are driven by three-phase electric motors with speed control via Inverter.

A PLC controls the speed of the gear pumps thus allowing to realize the mixing ratio; it is therefore possible to vary the mixing ratios, the extrusion speed of the products while keeping the ratio between “A” and “B” constant.

The mixing ratio is variable between 10 and 100% by volume. (with flow rates according to the mixing ratio and characteristics of the material)

The dispensing speed, the mixing ratio are adjustable through the control PLC.

Maximum Pot-Life time parameter adjustable from 10 sec to 30 minutes with critical threshold alarm.

In the event of a Pot Life alarm, it is possible to reset the alarm by extruding a certain quantity of mixed product.

The dosed products are sent independently to a pneumatic gun with independent interception of the two components with manual handle and button with electric opening contact. At the outlet of the gun the two products ‘A’ and ‘B’ will be mixed by means of a static mixer of the “disposable” type.

Groups equipped with a washing pump for cleaning the static mixer.

Reviews

There are no reviews yet.