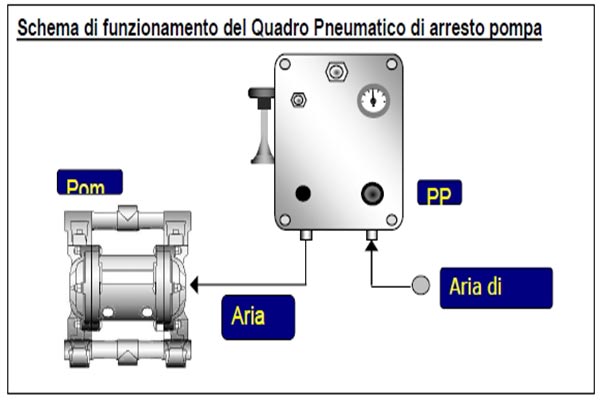

Description

Wagner pneumatic frequency meter

Frequency stop for diaphragm and piston pumps

A simple and reliable system

The frequency control device comes into operation when there is an air volume consumption higher than that preset at the pump inlet

This consumption can mainly be caused by 3 situations:

1. solid residues inside the pump

2. a break in the pipe downstream of the pump

3. excessive cavitation of the pump due to lack of product

The system is inserted through a pre-treated air flow regulator that intercepts excessive air consumption by blocking the pump and selecting an audible alarm

A reset command, via a button on the panel, will automatically put the pump back into operation

The timely intervention of the frequency meter alarm forces the operator to carry out the product priming operations correctly, avoiding an empty running

The advantages of using a frequency meter are:

Correct use of the pump in the pump priming phase

It prevents the pump from running idle with undesirable consequences

Limits the lack of product in the pipes (air bubbles)

Significantly extends the life of the pump seals reducing maintenance costs

The technical features:

Square dimensions 300x300x150 plus dimensions of the pneumatic siren about 100 mm

Positioning and wall fixing system

Button for the reset function

Pump block audible alarm

User manual, CE compliance

Reviews

There are no reviews yet.