Description

Wagner touch https://www.youtube.com/watch?v=udM6EAF7fu0&feature=youtu.be

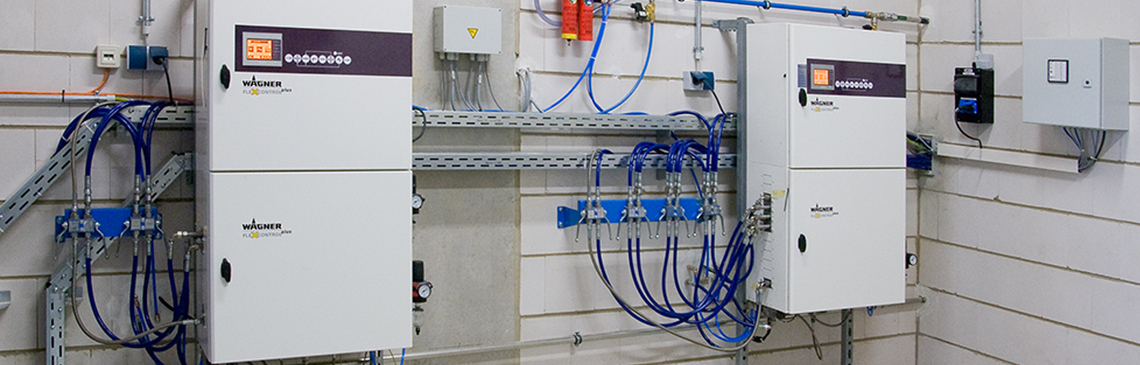

The latest generation of electronic mixing and proportioning units: the 2K Touch series represents the ideal solution for any application need (AirCoat, Airless, or pneumatic, conventional or electrostatic atomization).

Huge benefits

• Maximum precision and reliability;

• Simple to use and intuitive;

• Quick return on investment.

The systems have been developed to optimize quick color change and washing operations in order to minimize waste and save useful time for production activities.

Intellimix touch plus DFS has been developed to meet the frequent requests to manage mixed cycles with a single control panel to simplify the system and contain costs. In fact, it contains the potential of two electronic mixing units in a single solution.

The large 5.7 ″ touch screen with which the DFS touch plus is equipped allows you to manage all the parameters relating to the two circuits in an easy and intuitive way.

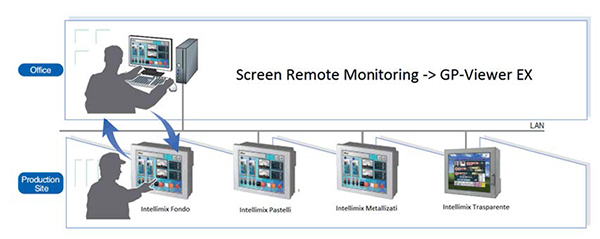

It is equipped with an ethernet port that allows you to use the remote diagnosis service and remote control of the system, as well as a very fast data exchange.

Intellimix touch plus DFS minimizes the waste of time, product and space, substantially enriching the already high potential of the Intellimix touch series.

It is the optimal solution to manage two distinct fluid sections in parallel which allow you to apply without problems even incompatible products such as water / solvent or epoxy / polyurethane.

Available options:

|

Proportioning system for 3K and 4K products |

on request |

|

|

Atex version |

on request |

|

|

Robot interface (clean contacts) |

on request |

|

|

Connection to max. two gun flush boxes |

on request |

|

|

Remote control (pneumatic) |

on request |

|

|

Air-solvent washing |

on request |

|

|

Gun control |

on request |

|

|

Independent power supply kit for 2 guns |

on request |

We have a wide range of mixing and proportioning systems, fully customizable and able to meet the application needs of each company.

Huge benefits

• The eight buttons on the control panel (four per circuit) make

the main daily operations (Start, Stop, Washing,

Recipe Change ) easy, especially in the case of manual applications;

• Extreme precision of the mixing ratio (± 1%) thanks to the

ProFace PLC : no risk of proportioning or mixing errors;

• Reduction of the time required for color change;

• Mixing of only the product used, no waste of

catalysed product ;

• Saving of product and solvent;

• Improvement of the quality of finishes;

• Control of consumption by production lot, by assigned recipe;

• Increase in productivity;

• Fast return on investment.

Supplied

• Electro-pneumatic panel with electronic management panel;

• 5.7 ″ Touch Screen Display;

• Ethernet and USB port for total download and back-up / restore of

stored recipes;

• Fluid section with product inlets and outlets and flow meters;

• Support frame.

Reviews

There are no reviews yet.