Description

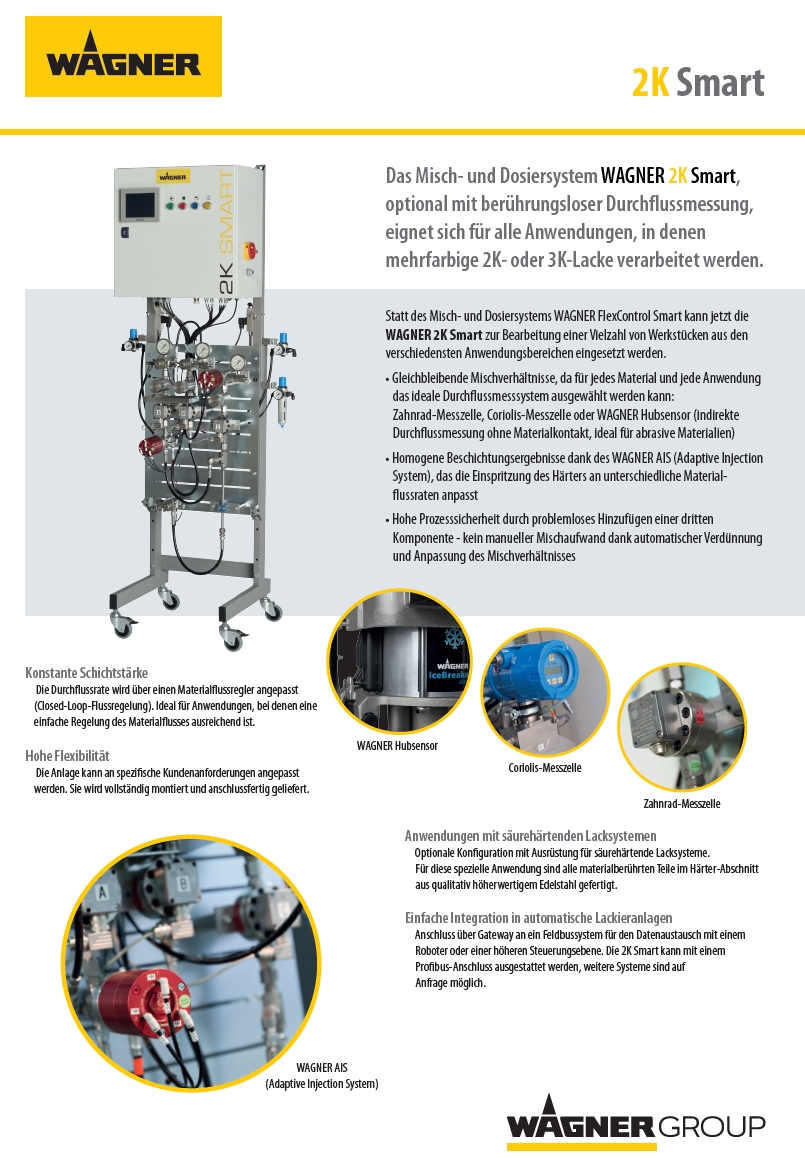

2K electronic mixing system for up to five colors and three components

Benefits:

Compact

The compact fluid part is designed to save space. The design allows for the shortest possible material paths and thus optimizes material and detergent consumption

Easy to use

Intuitive menu navigation via color display and four operating elements: start, stop, rinse and recipe change

Reliable

Precise measurement of material flow by means of a gear measuring cell, stroke sensor or Coriolis mass flow meter and precise metering with Wagner injection valves ensure constant mixing ratios and a high degree of homogeneity even with ratios minimum mixing

Technical specifications:

Colors up to 5

Stronger up to 2

Maximum third component 1

Flow measurement system Wagner stroke sensor, measuring cell for gears, Coriolis measuring cell

Number of guns Max. 2 with separate service life monitoring and separate rinsing

Atex Atex and non-Atex versions available, connection set up to 50 m

3.5 or 5.7 inch screen

High pressure or low pressure with special valves

Adaptive injection system (AIS) for components B and C

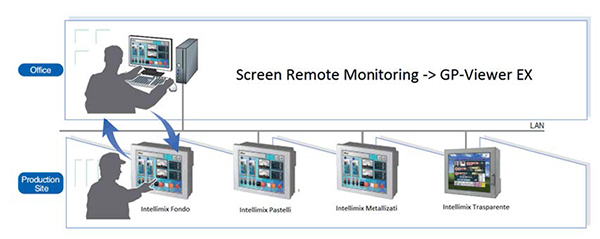

Communication Fieldbus gateway or digital digital I / O

Data archiving via USB or LAN connection (in combination with data archiving software)

Electrostatic shutdown for up to two VM 5000 / EPG 5000

Manual material pressure regulator (maximum pressure during washing) or digital (flow control)

Remote control cable max 45 m, usable in zone 1, with recipe change

In-line filter material filter

Reviews

There are no reviews yet.